The SS 1200-LF-S2-H2O is recommended for liquid samples with heavy free water contamination. These uniquely demanding applications require the highest liquid-liquid separation. The SS 1200-LF-S2-H2O provides even greater separation of water from liquid samples than the standard SS1200-LF, which is the best separator on the market today. The 10” hydrophobic filter in the first chamber separates the slip stream from the water in the fast loop. Any residual carryover of water is separated kinetically in the second chamber and is further polished by the 2.25” pure PTFE filter in the upper portion of the second chamber.

Kinetic Separation Technology is the most innovative technology available today for sample conditioning.

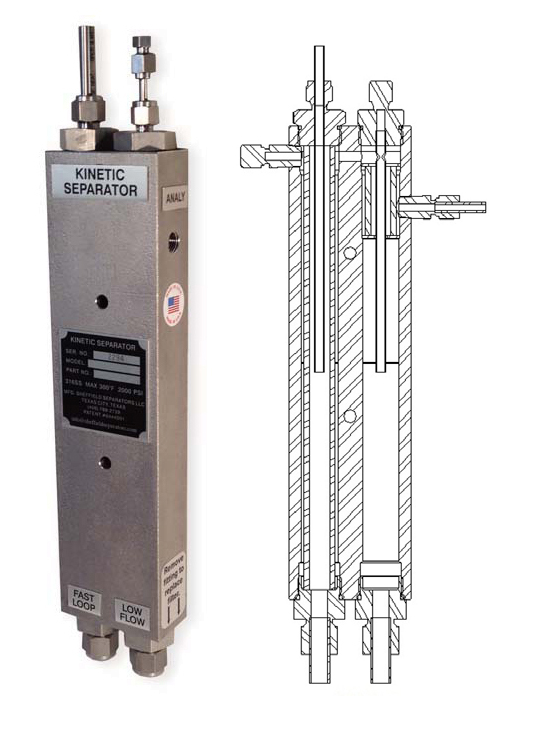

The Sheffield patented dual chamber separator provides maximum separation of heavy particulate. Although kinetic energy will physically separate impurities, it will not alter the chemical composition of the sample.

Features |

Benefits |

|

| Hydrophobic Filters in Both Chambers | Maximum water separation in both chambers | |

| Dual Graduated Filters 15/2 Porosity | More cost effective water separation and longer life for the pure PTFE Teflon filter in the second chamber | |

| Extremely Versatile | Operates across a wide range of pressure, flow rates, and temperatures | |

| Dual Chamber Construction | Maximizes separation and filtration; longer filter life | |

| No Moving Parts | Less maintenance, greater reliability | |

| Straight Fittings with O-ring Seals | Easier filter changes |

The Sheffield Kinetic Separator uses kinetic energy to separate the representative analyzer sample from impurities found in a process stream. This is accomplished by establishing a flow path through the 1st chamber and reversing the flow of a relatively small Bypass sample. Solid contaminants and immiscible liquids in the liquid samples will not negotiate this complete reversal of flow direction and exit the bottom of the separator. The Kinetic Energy caused by this reversal initially removes the impurities from the Bypass stream through gravity and inertia. To further effect this separation and filtration a second kinetic chamber with a hydrophobic filter polishes the sample. The second chamber also experiences Kinetic Energy Separation and removes the remaining impurities from the Slip Stream. The sample is lighter than immiscible liquids and solids (particulates) in a liquid sample.

How It Works

Initially, the flow path enters the first chamber. System pressure forces a reduced Bypass flow in the reverse direction; the main stream flow continues through the first chamber and exits the bottom of the separator. Gravity and inertia cause kinetic separation of the Bypass stream. The sample is lighter than immiscible liquids and particulate in a liquid sample.

The First Chamber of the Sheffield Kinetic Separator is designed for installation directly in-line to the Fast Loop sample transport system. This model embodies a special 10” – 15 micron Teflon-lined, hydrophobic, self-cleaning low pressure drop Fluorocarbon filter. The Kinetic Effect acts as a pre-filter. Most of the heavier contaminates are separated in the first chamber.

The Second Chamber separates and filters only the relatively small Slip Stream sample going to the analyzer which greatly enhances filter life. The second chamber is a kinetic energy polishing chamber, aided by a special 2.25”, 2 micron Teflon®, hydrophobic filter. Finally, both chambers exit the bottom of the separator to a common juncture with the return flow. These attributes combine to make the Sheffield Kinetic Separator virtually maintenance free.

The SS1200LF-S2-H20 is designed to remove large amounts of free water from a liquid hydrocarbon stream. The Kinetic Energy Separation removes most of the free water and particulate. The first chamber also utilizes the standard 10” 2 micron, Teflon lined hydrophobic filter. This removes the particulate and free water from the liquid hydrocarbon stream. The remainder of the free water is routed to the second chamber. At that point sample is polished by the second Kinetics Energy Separation. The extremely small, water droplets that become suspended in the liquid hydrocarbon stream upward towards the analyzer exit port are repelled by a special extremely hydrophobic filter.

Maximum Pressure: 2,000 PSIG

Minimum Pressure: 2 PSIG – Vacuum application with pump or eductor

Maximum Temperature: 300° F

Pressure Drop: 2 PSIG

Flow Rate: The flow rate specified for the sample system is sufficient for the separator. For best results, the first chamber flow should exceed that of the second chamber.