The SS700-LF-P2 is recommended for liquid samples with moderate to heavy particulate and light immiscible liquid contamination. These applications require a high performing, reliable separator and benefit from a parallel filter configuration. The SS700-LF-P2 is also recommended for applications requiring infrequent filter changes. In addition to the kinetic energy separation, which acts as a pre-filter, this model is equipped with fluorocarbon, Teflon ® lined filters configured in parallel to maximize surface area when only one porosity is required.

Kinetic Separation Technology is the most innovative technology available today for sample conditioning.

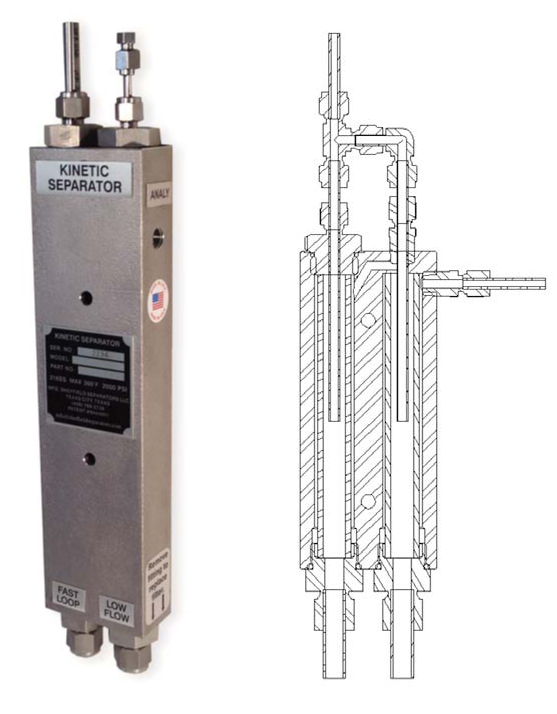

The Sheffield patented dual chamber separator provides maximum separation of immiscible liquids and particulate. Although kinetic energy will physically separate impurities, it will not alter the chemical composition of the sample.

Features |

Benefits |

|

| Extremely Versatile | Operates across a wide range of pressure, flow rates, and temperatures | |

| Hydrophobic Fluorocarbon Teflon® lined filters | Can handle significant amounts of free water or particulate without clogging | |

| Parallel Filters | Provides greater surface area resulting in more efficient filtration, especially in very heavy particulate loading, and less frequent filter changes | |

| Dual chamber construction | Maximizes separation and Filtration; longer filter life | |

| No moving parts | Less maintenance greater reliability | |

| Straight fittings with O-ring seals | Easier filter changes |

The Sheffield Kinetic Separator uses kinetic energy to separate the representative analyzer sample from impurities found in a process stream. This is accomplished by establishing a flow path through the 1st chamber and reversing the flow of a relatively small Bypass sample. Solid contaminants and immiscible liquids in the liquid samples will not negotiate this complete reversal of flow direction and exit the bottom of the separator. The Kinetic Energy caused by this reversal initially removes the impurities from the Bypass stream through gravity and inertia. To further effect this separation and filtration a second kinetic chamber with a hydrophobic filter polishes the sample. The second chamber also experiences Kinetic Energy Separation and removes the remaining impurities from the Slip Stream. The sample is lighter than immiscible liquids and solids (particulates) in a liquid sample.

How It Works

SS 700-LF-P2

Liquid with 2 Filters in Parallel

Initially, the flow path enters the first and second chamber. System pressure forces a reduced Slip Stream flow in the reverse direction; the main stream flow continues through the first and second chamber and exits the bottom of the filter housing. Gravity and inertia cause kinetic separation of the slip stream. The sample is lighter than immiscible liquids and particulate in a liquid sample.

Both Chambers of the Sheffield Kinetic Separator are designed for installation directly in-line to the Fast Loop sample transport system or within the Sample Conditioning System. This model embodies a special 10” 2 or 15 micron Teflon-lined, hydrophobic, self-cleaning low pressure drop Fluorocarbon filter. The Kinetic Effect acts as a pre-filter in both chambers.

Both filter elements have a special Teflon®-lined interior, which repels water and particles as these impurities pass through with the sample return. Finally, both chambers exit the bottom of the separator to a common juncture with the return flow. These attributes combine to make the Sheffield Kinetic Separator virtually maintenance free.

Maximum Pressure: 2,000 PSIG

Minimum Pressure: 2 PSIG – Vacuum application with pump or eductor

Maximum Temperature: 300° F

Pressure Drop: 2 PSIG

Flow Rate: The flow rate specified for the sample system is sufficient for the separator. For best results, the first chamber flow should exceed that of the second chamber.