The SS 1200-LF-S2-BF is recommended for liquid samples with heavy particulate loading. These demanding applications require the highest performance and the most reliable separator and filters. The SS1200-LF-S2-BF is also recommended for extremely fouled samples in applications where the backflush is necessary to maintain a reasonable run time. The coarser woven wire filters in the first chamber separate the heavier contaminants, while the finer pore size of the woven wire filters in the second chamber polishes the remaining contaminants.

Kinetic Separation Technology is the most innovative technology available today for sample conditioning.

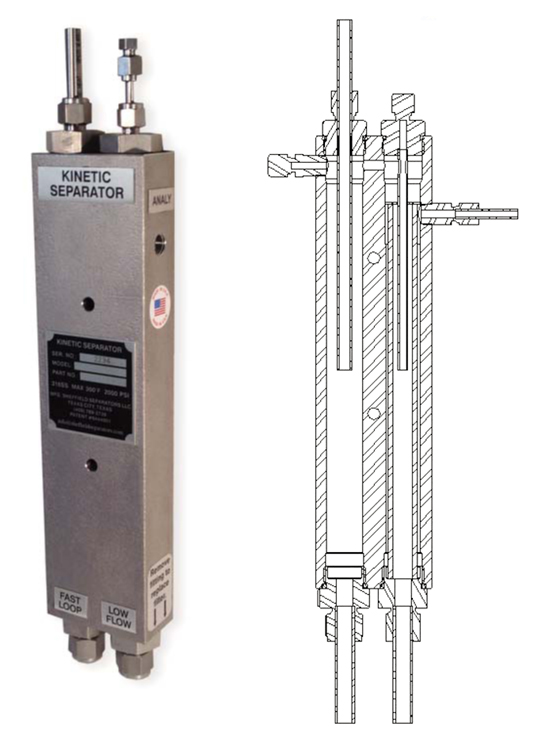

The Sheffield patented dual chamber separator provides maximum separation of heavy particulate. Although kinetic energy will physically separate impurities, it will not alter the chemical composition of the sample.

Features |

Benefits |

|

| Woven Wire Filters Designed for Backflush | Allows analysis of heavily fouled samples which could otherwise not be analyzed | |

| Dual Graduated Porosity Woven Wire Filtration in Series | Heaviest contaminates separated in first chamber and remainder contaminates polished in the second chamber results in the most efficient sample conditioning | |

| Extremely Versatile | Operates across a wide range of pressure, flow rates, and temperatures | |

| Dual Chamber Construction | Maximizes separation and filtration; longer filter life | |

| No Moving Parts | Less maintenance, greater reliability | |

| Straight Fittings with O-ring Seals | Easier filter changes |

The Sheffield Kinetic Separator uses kinetic energy to separate the representative analyzer sample from impurities found in a process stream. This is accomplished by establishing a flow path through the 1st chamber and reversing the flow of a relatively small Bypass sample. Solid contaminants and immiscible liquids in the liquid samples will not negotiate this complete reversal of flow direction and exit the bottom of the separator. The Kinetic Energy caused by this reversal initially removes the impurities from the Bypass stream through gravity and inertia. To further effect this separation and filtration a second kinetic chamber with a hydrophobic filter polishes the sample. The second chamber also experiences Kinetic Energy Separation and removes the remaining impurities from the Slip Stream. The sample is lighter than immiscible liquids and solids (particulates) in a liquid sample.

Blowback and Backflush Model

SS1200LF-S2-BF – SS1200GF-S2-BF

(Either can use Parallel Configuration)

Blowback and back flush sample conditioning systems are applications that are uniquely fitted for dual chamber Kinetic Energy Separation. The SS1200 Back flush model uses cylindrical woven wire stainless steel filters whose pore size is determined by the wire size and the density of wrapping. Whenever indicated, a woven filter appropriate for the specific coarse contaminant may be used in the first chamber and a depth filter specified for the analyzer sample may be used in the second chamber.

In the first and second chambers, the filters are stacked with a common internal path which exits to the return. To accommodate the heavy particulate loading seen in these applications, the first chamber is fitted with coarse filters and the second chamber, which is in series, has the specified porosity required for the analyzer. This filter housing can be easily back flushed with varying degrees of automation. The inside to outside path of the flow while in service is reversed, and the outside to inside path routes the back flush stream through the filters and then exists the existing return.

This application can be used with fouled water, heavy oils, catalyst blow back, or in applications in which the sample contains so much coarse contaminants that reasonable filter life is prevented.

Maximum Pressure: 2,000 PSIG

Minimum Pressure: 2 PSIG – Vacuum application with pump or eductor

Maximum Temperature: 300° F

Pressure Drop: 2 PSIG

Optimum Flow Rate:

GAS: First Chamber Exit: 20-50 SCFH.

Second Chamber Exit: 10-15 SCFH

LIQUID: First Chamber Exit: .5-1.5 GPM

Second Chamber Exit: 3-6 GPH